Braking Tech

Power is nothing without control. The braking system on your vehicle is an area

that must never be overlooked when tuning or modifying. You will not need to upgrade your brakes after

fitting an etune chip or Remap, but better braking

improves safety at all times, and can shave seconds off lap times. All vehicles can have their brakes

upgraded, even if it's just a better fluid.

Power is nothing without control. The braking system on your vehicle is an area

that must never be overlooked when tuning or modifying. You will not need to upgrade your brakes after

fitting an etune chip or Remap, but better braking

improves safety at all times, and can shave seconds off lap times. All vehicles can have their brakes

upgraded, even if it's just a better fluid.

For standard applications, the first thing that anyone can do is change the brake fluid to a higher spec.

There are 2 main groups of brake fluid, Silicone based, and Glycol based. Silicone fluids will

be marked as DOT5, and are relatively uncommon in domestic vehicles. The benefit of a silicone DOT5 fluid is

a long service life, as it will not absorb moisture from the atmosphere. The drawback is any moisture in the system

is not absorbed into the fluid, and can pool in low areas, such as the calipers or brake cylinders. This moisture can then

corrode the components internally, and lead to failing brakes or brake fade from boiling.

Glycol based fluids, although they will absorb moisture, it mixes fully with the fluid to leave no free

water, but the water content does affect the boiling point, making a "damp" fluid more prone to boiling.

Fluids that are Glycol based are marked at DOT3, DOT4 and DOT5.1.

For the more usual Glycol fluids, choosing the right one is vital.

| Dry boiling temp | Wet boiling temp | |

|---|---|---|

| DOT 3 | 205°C / 401°F | 140°C / 284°F |

| DOT 4 | 230°C / 446°F | 155°C / 311°F |

| DOT 5 | 260°C / 500°F | 180°C / 356°F |

| DOT 5.1 | 270°C / 518°F | 190°C / 374°F |

From the table above, you can see how the Glycol fluids (highlighted blue), increase in boiling temps for both new (dry) and old (wet). This isn't the end of the story though, as these are the minimum boiling temps.

High performance fluids will exceed these levels by a large amount, and what's more, the high

performance fluids are all DOT4 rated.

A high quality DOT4 is far better than a DOT5.1, so always compare the performance between fluids to

find the best one for you.

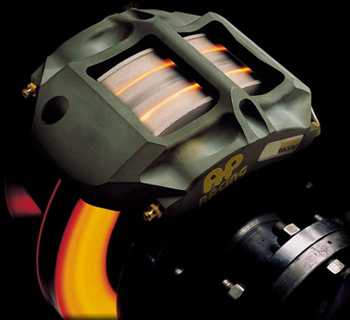

Discs and Pads

Good discs and pads will also improve braking performance, but it is the pads that make the biggest difference. There are a few different disc designs, each with their own pros and cons.

- Grooved discs - The grooves cut into the disc face are designed to allow gasses built up under heavy braking from forming a boundary layer and holding the pads away from the disc. This occurs only under heavy use and is generally overkill for street driving. The presence of the grooves will cut down the size of the contact patch between the pad and disc and can reduce braking effect. For racing applications, this effect is outweighed by the de-gassing properties, but unless under heavy use, performance will be slightly less. There will also be considerable noise under many circumstances.

- Drilled discs - These discs have numerous holes passing through them. The holes are designed to help cool the disc by allowing air to pass through the metal. Whilst this is effective, the holes can produce stress risers, making cracking of the discs under expansion quite common. Radiusing or casting the disc with the holes already formed helps alleviate these stresses.

- Floating discs - Often coming is 2 replaceable sections, the floating disc has a central bell which mounts to the hub, and a disc rotor that attached using sliding bolts or pins to allow it to expand separate to the centre. This system is used on almost every race vehicle or big brake kit, as it can take more heat without deforming as the disc tries to expand more than a cooler centre. The lighter alloy bell also decreases rotating and unsprung mass. Floating discs offer better performance that drilled or grooved discs, and although expensive, are sometimes seen as standard OEM parts on more performance orientated cars.

With good discs and fluid, a good set of pads is next. Performance pads will often some in

various applications, such as fast road, track and race. Fast road pads should have a higher temperature

resistance, and a greater Co-efficient of Friction. They will allow harder braking for longer, provide more grip,

and with only slight increases in brake dust.

Track pads will be a level above this, still providing good friction at hot and cold temperatures, but will

often wear the discs faster, and produce more dust than original equipment pads. In some cases they will be noisier,

as they might not have an anti-squeal backing which can melt or burn under the high temps produced.

Race pads are designed purely for racing applications. Friction when cold is often very poor so it is not

recommended to use these on the road, as they need high temperatures to function effectively. They will be very harsh on the discs,

create a lot of dust and will wear quickly. When cold, they can also squeal under any use, but for racing use, these drawbacks are

greatly outweighed by the stopping capability.

With the right choice of pads, discs and fluid, your braking ability and safety can quite easily be

upgraded. Understanding what is right for your needs is vital. One weak part of the system will hold back the others, but a

well thought out package will pay dividends.