How a Chassis Dyno Works

A Dyno or Dynomometer is a device for measuring force (which can then be converted into power)

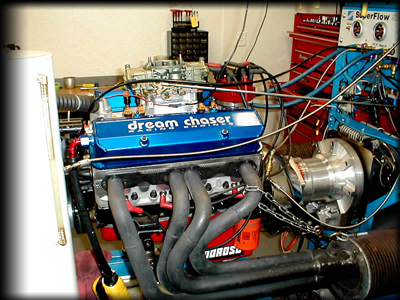

and for vehicles, there are 2 main types. The Engine Dyno attaches to the crankshaft and measures the raw torque or power from the engine against a brake.

This is the "Brake" of Brake Horse Power.

To use one of these, you need to remove the engine from the car, so they tend to be used just for development work and race engine building.

The other type, which we will be concentrating on is the Chassis Dyno.

A Dyno or Dynomometer is a device for measuring force (which can then be converted into power)

and for vehicles, there are 2 main types. The Engine Dyno attaches to the crankshaft and measures the raw torque or power from the engine against a brake.

This is the "Brake" of Brake Horse Power.

To use one of these, you need to remove the engine from the car, so they tend to be used just for development work and race engine building.

The other type, which we will be concentrating on is the Chassis Dyno.

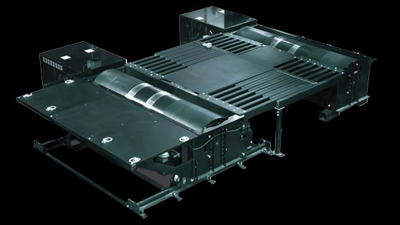

The Chassis Dyno is the familiar set of rollers that you drive a car onto, also known as a Rolling Road.

The Chassis Dyno is far quicker to test a vehicle's power output, with a complete measurement available in about 15 minutes

from turning up to holding the sheet in your hand.

How to prepare and what to expect

Although you can use a Dyno to get a closer look at the vehicle under load and at high speeds,

the primary objective is usually power measurement or tuning. Before you go, check your car over for fluid levels,

leaks, tyres, tyre pressure and suspension components, and general roadworthyness. Many Dyno centres will refuse a vehicle in poor condition

which may damage itself or the Dyno under testing. If you have access to any fault code readers, get it checked before. Many Dyno centres will

have diagnostic equipment handy, but ideally, you'll want to get everything in good condition before you test it,

otherwise you may well get lower power readings from the effect of the faults.

Once you are happy with the car, and it is ready for the test, take it for a short drive to get up to operating temperature

and get it to the Dyno centre. All vehicles have an operating temperature they were designed to operate at.

and at cooler temperatures will usually have a reduced power output.

When everything is ready, the Dyno operator will take your car, and drive it onto the rollers. It will then be strapped down

to prevent movement. The main point of the strapping is to prevent side to side movement and the vehicle coming off the rollers.

There will usually also be further straps to prevent it driving off the end, so bring towing eyes if you have them to

give an easy strapping point.

If the car does come off the rollers, it won't fly straight through the nearest wall though. At that stage, just the wheels and drive

train are moving, the car doesn't have any inertia itself as it isn't moving, but these cases are very rare.

Once strapped down, measurements will be taken of tyre sizes, pressures, oil temperatures, air temperatures (both intake and ambient, although

ambient temperature is the important one, Intake temp is a data guide, and frequently irrelevant to driving conditions

as the vehicle is being cooled by a fan, and the bonnet will usually be up too)

A calibration run is then made. As there should be no slip in the gears, the engine RPM is proportional

to the wheel speed. From this, the Dyno can plot the torque produced at a certain roller speed and match it up to the

RPM of the engine. Some systems also have further direct RPM measurement, so any wheel spin / slip can be detected

as a difference between the speed the rollers are rotating at and the speed the wheels should be at.

A calibration run is then made. As there should be no slip in the gears, the engine RPM is proportional

to the wheel speed. From this, the Dyno can plot the torque produced at a certain roller speed and match it up to the

RPM of the engine. Some systems also have further direct RPM measurement, so any wheel spin / slip can be detected

as a difference between the speed the rollers are rotating at and the speed the wheels should be at.

Now that the Dyno computer has all the engine data, the run can start.

This is the fun bit! Although you won't be able to stand near the car whilst under testing, you'll still be able to hear the noise it makes

from quite a distance. A large cooling fan will be directed at the engine to provide the cooling air it would otherwise be getting whilst driving.

From a fast idle, the operator will then hit full throttle and let the car accelerate the rollers as fast as it can

until it reaches the redline, and then release the accelerator pedal, and hit the clutch.

The strange noise you'll hear now is a mix between valve train noise and gears and it can be quite a loud, unnerving experience.

The vehicle will be left to decelerate by itself, still in the chosen gear, until it reaches the start speed again.

The purpose of the Run Down is to measure the drag from the drivetrain. It isn't perfect, but it's the best

way to estimate the frictional losses that the car has to force through, and this Drivetrain loss will be added onto

the Wheel power measurement to give an estimate of the power that the engine is producing.

Keeping it with just the clutch depressed isolates any engine braking that will appear as a greater drivetrain loss, and still measure the

frictional losses as best it can through to the gearbox.

The Dyno computer will then calculate a number of different values, Wheel power, Flywheel Torque,

Estimated Flywheel power, Drivetrain loss, and also present the power figures in both corrected and uncorrected forms. We'll cover the

correction factors in the next section.

The Physics of Power

Power is a measurement of Torque with respect to the rate at which is it making it. For an

engine, it is quite simply expressed as-

Power = Torque x 2π x Rotational Speed

and this can be further simplified to-

Power (hp) = (Torque x RPM) / 5252

So, you can see Power is created from the measurement of torque and the speed at

which the torque is being produced. The Chassis Dyno has an accurate measurement of the

Speeds from the calibration or direct readings from the roller speed and engine speed. What it needs

is to find out the torque produced.

Torque is a rotational force, and Force is put simply as-

Force (N) = Mass x Acceleration

Torque depends on how much leverage this force has on a pivot, and you'll see

it quoted as Nm or Newton Meters.

The Dyno measures the acceleration of the mass (the rollers) to find the force applied

and calculates the power from the Speed at which they are turning.

There are further points that are covered inside the Dyno software which is the Inertia of

the rollers.

Inertia is the tendency for something to either stay still if it isn't moving, or to keep moving unless

anything else acts upon it.

The mass of the Roller isn't as important as it's inertia. The Inertia can give an effective mass, as just the

weight of the roller won't relate to how easy it is to turn. For example, a 1 ton roller with the mass all in the

outer skin of the drum will have more inertia than one with the mass centred in the middle with a

thin outer skin.

These calculations are made in the factory and design of the rollers and aren't needed to be

calculated once they have been built in.

So back to the measurement, the Dyno computer measures the acceleration of the roller, which has a

known "mass" and will tell you the Force used.

From the other data already known, it changes the Force into the torque applied to the roller, and

with the rotational speed it can now tell you the Wheel Power.

Next, in reverse, it will measure the deceleration of the rollers to work out the Transmission losses,

also known as Drag Power. The Wheel Power plus the Drag Power gives the estimated Flywheel Power

Finally, the Flywheel power is ran through the Power calculation to give the Flywheel Torque.

Torque at the wheels isn't given, as this varies depending on the gear used.

Correction factors can then be applied to the data. These correction factors allow

variables such as Ambient Air Pressure and Temperature to be factored out. This way you can

compare Dyno charts made on different days, under different conditions without those factors influencing

the overall corrected figure.

Types of Chassis Dyno

The information given above talks mainly about Inertia Dynos but there is another type which

is the Braked Dyno.

Braked Dynos use Absorbers to hold a braking force on the rollers. The force is variable, so if a resisting torque

of 150Nm is being applied by the Absorber, the engine speed will also stay at the same speed when the engine is producing 150Nm.

If the engine is producing more torque, it will accelerate, or if less torque, it will decelerate.

The benefit of a braked Dyno is that an engine can be held at a certain RPM, and the braking force adjusted so the engine

won't accelerate or decelerate, and you can then read off the Absorber torque knowing that it matches the engine torque.

If adjustments to the engine tuning are made, you can see the effect if it accelerates or decelerates the rollers. Braked

Dynos can also produce a full power sweep by having an adjusting Torque load or Ramp Angle so the car

can accelerate from idle to max RPMs whilst measuring the output. Certain Dynos can operate in

both an Inertia fast sweep mode, or a static load power absorbing braked mode.

Problems with Dynos

There are still some flaws with Dynos and factors that need

to be considered. The main one is the Transmission loss which can't accurately measure gears moving forwards

under high loads by estimating from unloaded gears now acting as brakes on the wheels.

The Transmission loss can also be used to "fake" results by adding artificial extra loads such as engine braking, or the

vehicle's brakes which then get added to the final result.

Twin Roller Dynos use two small drums with the wheel sitting in the middle. These rollers will "poke" into the tyre

more, and two deflection patches will add to lost power and can heat the tyres up significantly compared to Single Roller Dynos.

Single Roller Dynos use a far larger drum which provides a more natural contact patch for the tyre, and also allows

vehicles with lower ground clearance to use them as the vehicle sits onto of the single drum rather than in a dip between 2 small rollers.

Twin Roller Dynos are more compact as the roller diameter allows them to be easily driven onto using ramps.

Single Roller Dynos will either need larger ramps to gain the required height or a hole made to sink them into,

keeping them level with the existing floor.

Automatic Transmission equipped cars can have further problems as the car will try to change gear during the

acceleration, and the Transmission loss can't be measured unless put into neutral, which then will remove

any frictional losses that could have been measured in the gearbox.

The Wheel Power figure will still be accurate, so you can always compare Wheel powers

between an automatic and a manual transmission car, or likewise, comparisons against itself will

still show increases in power at the wheels.

4WD cars will require a 4WD Dyno, but often the Traction Control Systems will panic as they try to

balance the power output to the front and rear axles, which can turn at different speeds. Specialised

linked Dynos are available that can lock the front and rear roller sets together.

Traction control in 2WD cars can also cause problems as they just see the driving wheels moving

and nothing from the Wheel Speed ABS Sensors, so the may limit power expecting it to be Wheel Spin. For a similar reason,

ABS fault codes will usually be generated when the vehicle only detects movement on the driven wheels.